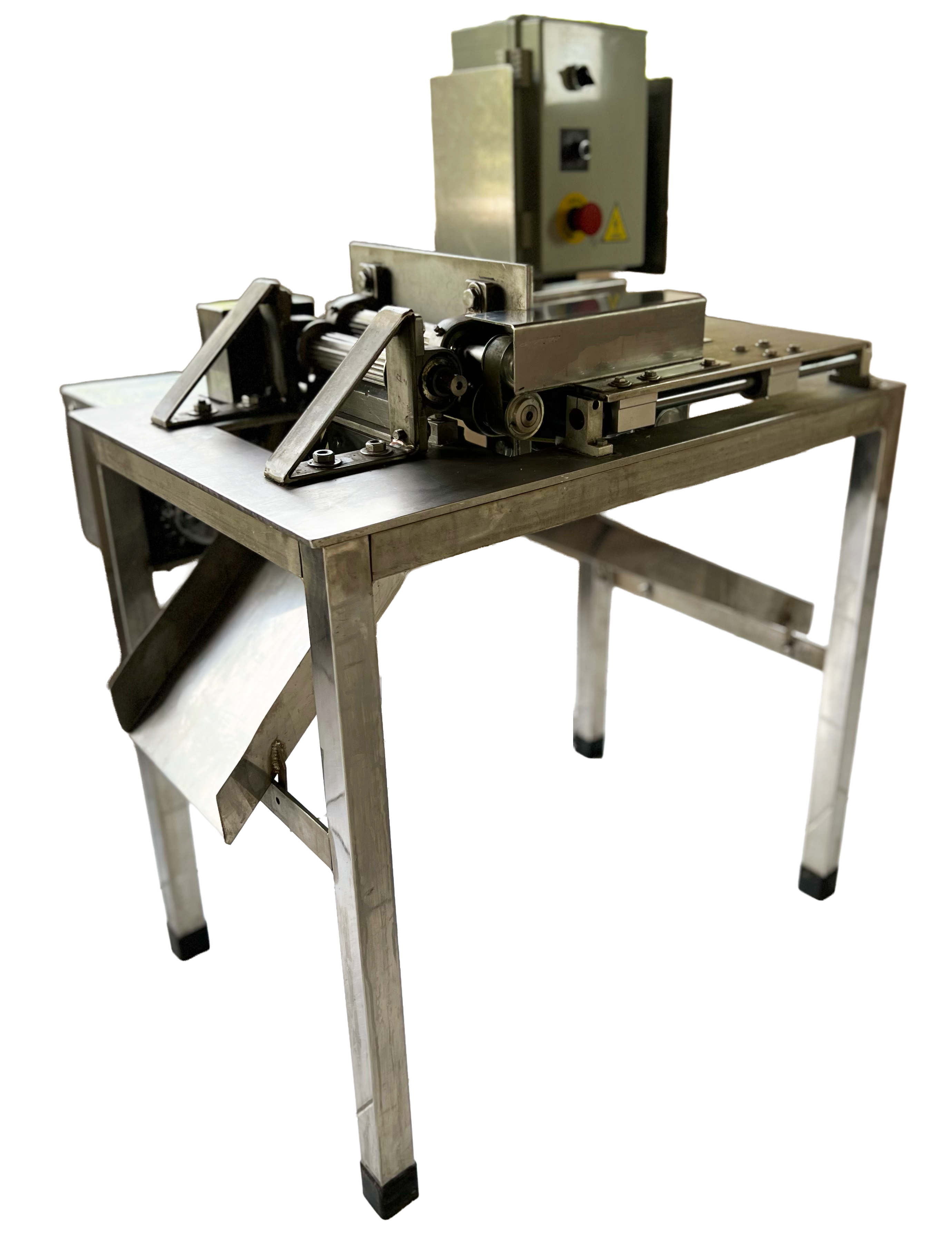

Machine for peeling and slicing cassava.

The peeling process of cassava billets is performed by three traction rollers that rotate the billets against a fixed cutting blade; the approach is manually actuated.

- Two 0.33 HP three‑phase motors powered by a frequency inverter (single‑phase input) with speed control

- Constructed in AISI 304 stainless steel

Features & Benefits

Cut Precision

Adjustable thickness from 0.5 mm to 3 mm, removing core fibers.

High Productivity

Up to 200 kg/hour (may vary with cassava quality).

Versatility

Allows billets to be cut vertically or diagonally.

Ease of Use

Fast, simple and safe feeding.

Easy Cleaning

Materials and design facilitate sanitation.

Machine Specifications

| Structure: | Built from non‑corrosive material, with plates and shafts in AISI 304 stainless steel, compliant with ANVISA standards. Easy to clean and maintain. |

|---|---|

| Cutting system | Rotation of cassava billets by three rollers manually approached to a fixed cutting blade. Traction rollers are non‑cutting, ensuring operator safety. |

| Motors | Two 0.33 HP three‑phase WEG motors, powered from a single‑phase supply via frequency inverters with speed control. Electrical voltage: 220 VAC (option 110/220 VAC). |

| External dimensions | Length: 800 mm Width: 700 mm Height: 880 mm |

| Specific heights | Feeding height: 850 mm Discharge height (peeled): 320 mm Discharge height (sliced): 350 mm |

| Billet dimensions | Thickness: 20 – 100 mm Length: 40 – 150 mm |

Productivity

Production capacity – Peeled

Approximately 170 kg/hour.

Production capacity – Sliced

Up to 200 kg/hour.

Efficient preparation solution

We understand the challenges farmers face every day in preparing cassava for the consumer's table.

Process agility, waste reduction and optimization are fundamental to ensure successful peeling and slicing.

With engineering expertise and hands‑on experience, we are ready to tackle this job by your side.

We take pride in helping our customers innovate with exclusive turning‑based slicing of table cassava for countless culinary recipes.

- Engineering applied to table cassava preparation.

- Efficiency, quality and waste reduction.

- Innovation in peeling and turning‑based slicing.

Table Cassava Preparation

The Mamaai machine revolutionizes preparation by turning the root into thin slices, removing fibers and respecting the Slow Food philosophy.

Hot Dishes

Soups, casseroles, "vaca atolada", feijoada, purées and gratins.

Pastas & Snacks

Gnocchi, empanadas, fritters, breads, pies, cakes and more.

Baked & Fried

Crispy chips, air‑fried fries, grilled and light bakes.

Safety

The Mamaai machine is easy to feed and offers high operator safety.

Cleaning

Cleaning is practical, with easy access to all parts.

Pre‑Peeling Tips

Before using the Mamaai machine, follow these guidelines for best performance and to avoid damage:

- Wash the roots thoroughly to remove sand.

- Cut billets with a minimum diameter of 4 cm.

- Ideal thickness: 2 cm to 10 cm.

- Ideal length: 4 cm to 15 cm.